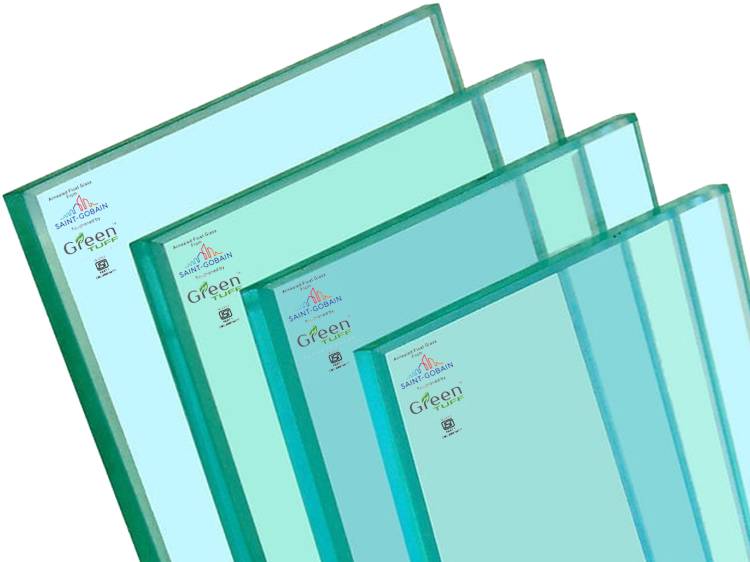

Tempered / Toughened Glass

Tempered or toughened glass is a safety glass made by heating and rapidly cooling it, resulting in remarkable strength and impact resistance. It also handles temperature fluctuations without cracking, making it perfect for high-temperature.

Much of the glass that’s used for residential and commercial applications is tempered safety glass. In short, tempered glass is heat-treated, making it about 4x stronger than regular, annealed glass. By design, when broken, tempered glass disintegrates into small pieces and is much less likely to do harm.

Toughened Glass

Toughened glass is a safety glass that has undergone processes of controlled thermal treatment to increase its strength. Also known as ‘Tempered glass’, toughened glass is made from annealed glass that has been heated to approximately 650⁰C and then rapidly cooled, making it four times stronger than the ordinary glass.

Due to the increased heat treatment and rapid cooling of the glass, the treatment produces different physical properties. This results in compressive stress on the surface and improved bending strength of the glass. Before toughening, the glass must be cut to the correct size or pressed to shape.

The Process of Toughening

The glass is carried by rollers and goes through the furnace. Three types of modes are used to heat the glass – conduction, convection and radiation. While the rollers help to conduct the heat, the coils enable radiation of heat. This ensures that the glass is evenly heated on every side. By blasting air on both the surfaces, the heated glass is then cooled uniformly.

Characteristics of Toughened Glass

After toughening, glass can neither be cut, nor altered.

Toughening does not alter the basic characteristics of glass – like light transmission or solar heat reflection. Glass toughened is known to have higher thermal strength, with the ability to withstand high temperatures up to 250°C.

Toughened glass is difficult to break but in the event of a breakage, disintegrates into small, harmless blunt pieces.